If, as Margaret Fuller once said, “wine is earth’s answer to the sun”, it makes sense to harness the power of the sun to make our wines. In sunny South Africa it seems a clear solution to help wine producers not only reduce their carbon footprint and energy costs, but to also create a sustainable energy resource, with the advantage of not having to rely on Eskom. More South African wineries are seeing the benefits of going solar.

Many wineries and winemakers are eager to incorporate sustainable practices into their farming operations. The export industry requirements increasingly compel them to do so. Solar electricity is a step forward that makes sense in our sunny climate, with the Western Cape averaging more than 2993 hours of sunlight per year (of a possible 4383) and an average of more than eight hours of sunlight per day.

Most businesses don’t have in-house engineering skills, so it makes sense to contract external service providers in the conversion to sustainable energy management. This entails understanding not only the technical intricacies but also the sensitivities particular to each farm.

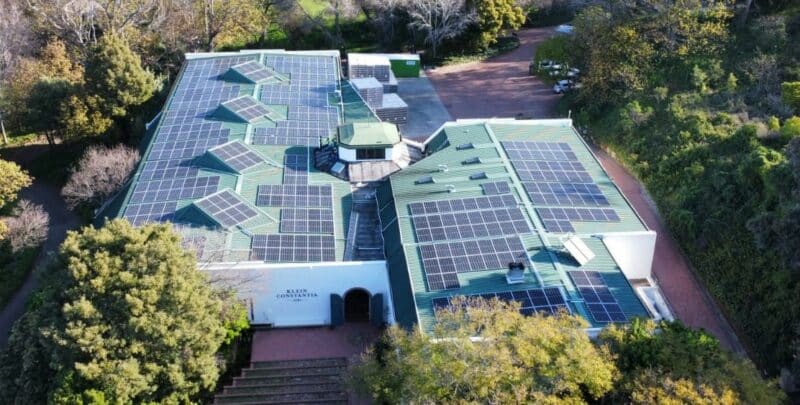

Case study: Klein Constantia

Recently, two iconic Western Cape wine estates committed to adopting a more holistic approach to energy efficiency and sustainability by incorporating large battery banks into their solar photovoltaic (PV) installations.

Klein Constantia was awarded Conservation Champion status in 2011 by the Worldwide Fund for Nature (WWF), in recognition of its commitment to regenerative farming practices, including conserving natural systems and biodiversity on the land and optimal water and energy efficiency. Installing solar and batteries is consistent with this practice. Klein Constantia has been a strong proponent of renewable energy and upgraded their eight-year-old PV installation in mid-2022 to close to 175 kWp (kilowatt ‘peak’ power output).

Larry Fitnum, MD of Energy Capital Western Cape, says that apart from reducing costs it was also an opportunity to supplement as much of the grid energy consumption as possible, achieving a 46% supplementation high in January 2023. This presented an opportunity to export power back into the grid, but the decision was taken to invest in a large battery to store the surplus energy and to alleviate the threat of load shedding, especially with the 2024 harvest fast approaching.

- Klein Constantia’s 300 kW battery is housed in a substantial and purpose-built battery and inverter room.

Planning and implementation

Careful preparation and planning are key when deciding on the battery specifications, location of the battery and available budget, Larry says. This process meant that a battery room was purpose-built for the sole reason of housing the battery in a well-managed and controlled environment.

Rather than long cable runs, and to enable easier installation using rigid cables running directly from the battery room to the tie-in points, deep trunking was cut into the floor of the existing reinforced concrete cellar entrance. The battery room is an external concrete structure designed in collaboration with the Estate’s contracted architect to complement the cellar buildings and be inconspicuous to tourists and visitors to the wine cellar.

Vineyard Manager Craig Harris pushed hard to have the installation completed and operating smoothly before the festive season break. “With all the various initiatives we undertake on the farm to drive for sustainability, it is a no brainer that the battery is a good solution for the environment, and energy security is also a business imperative if Matt (Day) and his team are to continue to make the magic they do.”

“The cost of the installation is substantial and has been a material spend on a significant asset, but it is also essential if we are going to show our commitment to the environment as the custodians of the farm for generations to follow,” adds CEO Pascal Asrin.

An aerial view of the solar roof installation at Klein Constantia.

Outcomes

Winemaking requires a lot of electricity, and if this can be regulated by making reductions in this area of wine production, the money saved can be put to greater use.

Larry adds that the project had its challenges but has been most rewarding. There was complete buy-in from management and they remained part of the process. When asked about some of the challenges, he stressed the importance of understanding the client’s objectives and then having a clear picture of the energy demand profile and the seasonality.

“The farm was operating efficiently so there was little we could do to reduce the demand,” he says. “The roof was solar friendly with little shade but had smaller roofs with varying aspects to it. We therefore went with an optimised PV solution. The annual demand is very seasonal with higher energy consumption in summer when battery and energy security are important, but having a plan of what to do with an expensive asset in the quieter months makes it all the sweeter.”

Since beginning its operation eighteen months ago, the solar power system has realised a saving of 120 328 kg of CO2 emissions, significantly cutting the farm’s carbon footprint – equivalent to planting 3 352 trees. There will also be diesel cost savings and no emissions from the generator during load shedding.

Building solar systems with a 20-25-year life expectancy demands thorough planning and attention to detail. It is critical to prioritise the long-term operations and maintenance of the system. Safe access for cleaning and a lasting mounting structure are essential. If they aren’t factored into the design, the system’s output will suffer, with the result that the predicted yields won’t be reached. A solar PV plant’s lifespan can span decades, but this durability hinges on meticulous development, thorough planning, and quality workmanship.

“I want to focus on the wine and know that there will be energy when the cellar team needs it,” explains Matt Day, Klein Constantia’s winemaker for the past 14 years. “The fact that it is renewable is the great part”.

Case study: Thelema Mountain Vineyards

Gyles Webb, owner of Thelema Mountain Vineyards in Stellenbosch, initially invested in solar two years ago. More recently, he added batteries to offset the rising cost of diesel and give him peace of mind that energy was always available in the cellar.

As a wine producer, Thelema is a typical seasonal client with a usage profile well-suited to solar production hours, Larry says. ECWC designed and installed an appropriately sized solar system to maximise cost savings. “We installed a 109.6 kW optimised system on the most suitable roofs of existing cellar and outbuildings,” Larry says. “Thelema initially remained grid-tied and integrated with the existing generators. The system alone supplements 42% of the annual energy required. For this system, the payback period was conservatively estimated at just over three years.”

This solar power system, since beginning its operations just over two years ago, has realised 120 117 kg CO2 emissions saved significantly cutting the farm’s carbon footprint which is equivalent to planting 3 585 trees. Towards the end of 2023, Thelema decided to further relieve their reliance on Eskom and the exorbitant cost of diesel to run the generators by installing batteries to complement the existing solar system.

A drone Image of the rooftop solar installation at Thelema.

“The installation of the battery system at Thelema was marginally easier than at Klein Constantia,” Larry says. “At Thelema the battery size was also 300 kW and the weight of the battery alone is 2.2 tonnes. We opted for a customised containerised battery storage solution. The team at Energy Capital designed and built a compact container specific to Thelema which is close to a turnkey, plug-and-play solution. Most important was preparing a concrete plinth, with raised ribs, on which the container was placed, with the thick cabling exiting via the floor, through a hole in the plinth and underground to the tie-in point. Because aesthetics is essential at a wine estate which receives visitors, we hid the battery container among the trees, close to the grid and generator positions. The weight of the loaded container is approximately six tonnes and access routes and equipment required to place it meticulously on the plinth was carefully planned and undertaken by an experienced rigging crew.”

Batteries bring with them specific challenges. They must be kept cool, so included in the container are two air conditioning units, as well as a bespoke and accredited Lithium-Ion “flooding” fire suppression system in the unlikely event of a fire.

For Energy Capital Western Cape, working with these two iconic wine estates and to have a small part in ensuring they continue to produce their world-renowned wines and visitor experiences has been a privilege, Larry says. “There is now universal agreement that the wine industry’s energy consumption must be lowered. This can only be accomplished through two methods: behavioural modification and technological interventions.”

Why Renewable Energy makes Sense

Reducing energy costs, ensuring energy security as a business imperative, and ESG (Environment, Social issues, and Governance requirements) all start with understanding the business and strategic objective you are wanting to achieve.

Understanding these helps determine the priorities and therefore the equipment, design and cashflow required. Cost and cash flow determine the end result and how the design can be undertaken in a planned module and phased approach.

According to Larry Fitnum, MD of Energy Capital Western Cape, one needs to consider the following when designing a solar installation:

- the energy load profile and demand spikes i.e. seasonality of the demand and the “time-of-use” tariff, as well as the annual high and low season costs

- the structure i.e. roofs on which you place your panels must be fit for 20+ years and be approved before installation, or suitable land needs to be available for a ground mount

- the outlook for loadshedding i.e. it is becoming longer and more frequent

- the increasing cost of diesel and its emissions compared to the cost of batteries which are integrated with solar

- the financing options which may include PPA/Rent to own or and self-funded/bank-funded

- additional costs such as grid studies which may be required

- that genuine original Tier One equipment and materials are used

- the project must be signed off by a professional engineer.

- health and safety requirements during and after installation are essential to prevent accidents and ensure that proper maintenance and cleaning can be carried out.

Government has provided certain tax incentives to enable businesses to move to renewables sooner. This benefit expires at the end of March 2025.

Going completely off-grid can be expensive. The option of grid-tied power, using Eskom to supplement your system even though it is not reliable, may be more palatable.

Eskom offers the following tools to incentivise private energy production whilst remaining grid-tied:

- Wheeling – an agreement for lower cost energy and credits between a user (generator of energy) to a consumer using the grid infrastructure

- Offset – energy supply from where it is over produced to where it is required on the same farm i.e. from irrigation pumps not needed in Winter can be offset to staff housing for heating

- Banking – feeding surplus energy into the grid and drawing it back for own consumption when required during the same financial year

- Arbitrage – use batteries during expensive tariff hours and recharge them using solar during the day, or Eskom when solar not available and only during lower tariff periods

Harnessing any renewable energy source requires an initial investment. With solar energy, even small solar systems make financial sense as the technology is very modular. The bigger the system, the more panels are used. Solar is one of the most flexible sources as both smaller and large-scale systems tend to work favourably with the numbers.

Renewable energy is not only better for the environment, but more sustainable for your business. Whichever route you take, the best starting point is to thoroughly research your options.

WATCH: Energy Capital Western Cape solar PV installation at Klein Constantia