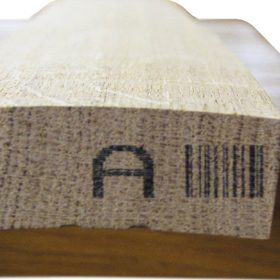

WOOD AND WINE UPDATEAs result of its nature, one of the most important problems experienced with wood barrels is the variation which exists between individual barrels. It is easy to specify physical properties like capacity, wood species, stave diameter, number and type of hoops, but factors like toasting degree and grain density are not easy to quantify and cooperages also differ with regard to their classification of different degrees. Coopers initially used the geographic origin of forests to differentiate between barrels. Nevers, Vosges, Troncait, Limousin and Allier were consequently part of barrel specifications. Winemakers have also based their expectations of the matured wines on the influences of these differences. It was only during the 1980s that the toasting degree became part of barrel specifications. By varying the toasting duration and intensity, coopers could supply barrels, which impart predictable flavours like vanillin, dry nuts, roasted almond and smoke to wine. Winemakers could add more complexity to their wines, which also created a new dimension for consumers. Cooperages continued research to offer more diversity to winemakers. This included inter alia the wood origin, wood leaching, wood drying and toasting. An important resulting action, was the selection of timber according to the grain, instead of the traditional origin classification. It contributed mainly to more uniformity amongst barrels delivered to cellars. The different wood grain classifications can be summarised as follows:

Generally longer maturation periods are required for increasing grain intensity. |  The grain of the wood plays an important role in the maturation period. |

The toasting degree of the barrel plays an important role in the flavour of the resulting wine. |

The extra fine or extra tight grain is the best choice for premium wines. Seeing that the timber used for it originates from slow growing trees, it leads to subtle and elegant flavours, which need a longer maturation period to balance the flavours. During the first 12 months the wine will exhibit a dusty oak, pencilly, timber-like character, which appear unbalanced. It is consequently important to choose the grain according to the required maturation period. The stage of optimal oak maturation is also influenced by the cellar temperature, the body of the wine, variety and analyses like alcohol concentration, pH and acid concentration. As soon as the oak maturation appears balanced, it must be terminated, seeing that further maturation will lead to excessive wood character, which can overwhelm the fruitiness of the wine.

Wine styles also changed over the recent years. Consumers prefer wines with soft tannins and delicate wood character, which are immediately drinkable, because most consumers do not mature wines in their own cellars before drinking it. The most wines are not matured for a long period and the maturation period must be kept as short as possible to improve the cash flow of the cellar. Winemakers must plan their wood maturation to comply with the consumers’ and business requirements. It can be done by considering the following aspects:

- The use of semi-fine or medium grain wood, which requires a shorter maturation period.

- The use of water instead of traditional open fire to bend the staves. It decreases the impact of the wood on the wine.

- The use of 300 or 500 ℓ barrels instead of 225 or 228 ℓ barrels, which decreases the surface-volume ratio of the barrels.

- The use of American oak. In combination with French oak it can lead to wines that are acceptable at an earlier stage of maturation.

- The degree of toasting must suit the wine and it must also be borne in mind that the toasting degrees differ between coopers.

- The outside seasoning and maturation of the wood can decrease the impact of the wood if it is extended.

- The use of alternative wood products offers possibilities to shorten the wood maturation period.

The decision to balance the wood character of wine, is mostly a compromise decision regarding the different factors which influence it (Little, 2015).

Reference

Little, Graeme, 2015. Latest directions in oak: Trends and the future. Australian & New Zealand Grapegrower & Winemaker, December 2015: 76 – 80